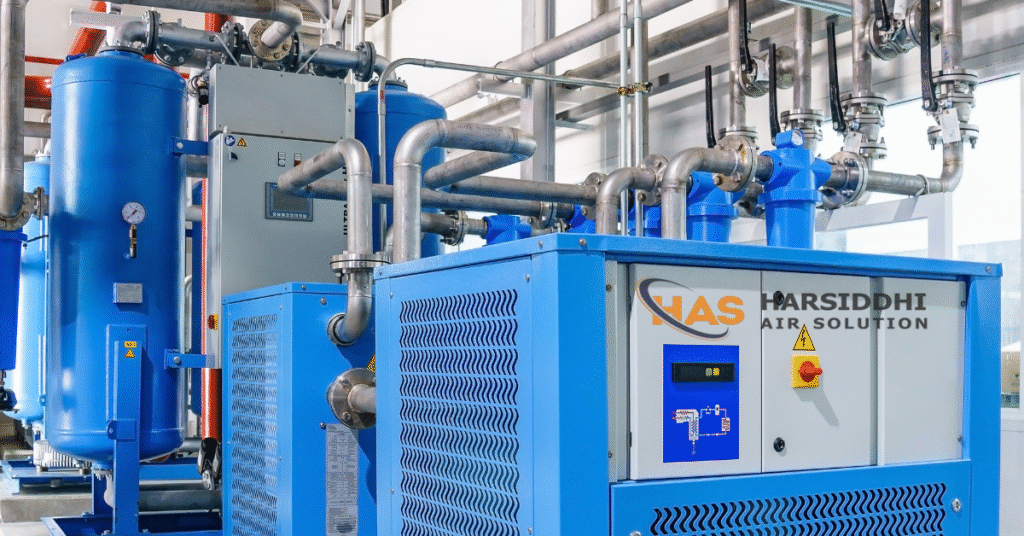

High-Performance Moisture Removal Systems for Industrial & Medical Use

Harsiddhi Air Solution designs & manufactures, high quality Compressed Air and Gas Dryers that are reliable, energy-efficient, and built to last. Our drying systems provide clean, dry, & moisture-free compressed air and gas for a variety of industrial & medical applications.

Whether you need a Heatless Desiccant Air Dryer, an Internally Heated Air Dryer, an Externally Heated Air Dryer, or a Refrigerated Air Dryer, we have the precisely engineered solution to keep your compressed air system dry, clean, and efficient, protecting your equipment & processes from costly damage and downtime.

What is the Importance of Compressed Air Dryers

Moisture is considered one of the biggest threats to compressed air systems. If air is not properly dried, it can lead to corrosion, clogged filters, and shorter life spans of pneumatic products.

Our Compressed Air & Gas Dryers can:

- Remove moisture, oil and contaminants from the air/gas

- Prevent rust and corrosion of pipelines and valves

- Protect pneumatic tools and instruments

- Guarantee a high-quality output during sensitive production processes

- Improve efficiency and reduce maintenance costs

With Harsiddhi Air Solution’s dryers, your compressed air is now clean, dry, and reliable – and won’t interrupt your operation.

Our Range of Compressed Air & Gas Dryers

Heatless Desiccant Air Dryer

A Heatless Desiccant Air Dryer removes moisture through adsorption utilizing the use of activated alumina or molecular sieve material. One tower dries the air while the other regenerates using a portion of dried air.

Features & Benefits of Heatless Desiccant Air Dryer:

- Easy, reliable and maintenance-free operation

- No external heating requirement

- Dew point as low as (-) 40°C or (-) 60°C

- Low installation and operation costs

Applications of Heatless Desiccant Air Dryer:

- Perfect for any packaging application, instruments and control air systems.

Internally Heated Desiccant Air Drye

This model utilizes internal heaters to regenerate the desiccant, lowering purge loss and energy use.

Features & Benefits of Internally Heated Desiccant Air Dryer:

- Dew point as low as (-) 60°C

- Low purge air cost

- PLC automatic control

- Longer desiccant life and lower energy cost.

Applications of Internally Heated Desiccant Air Dryer:

- Any continuous industrial operation that requires stable air quality.

Externally Heated Desiccant Air Drye

Externally Heated Air Dryers relies on external blowers and heaters to regenerate the desiccant resulting in a high level of energy efficiency along with long life.

Benefits of using Externally Heated Desiccant Air Dryer:

- Dew point of up to (-)70°C

- No purge air loss

- Heavy and durable construction

- Extended desiccant life and minimal maintenance

Application of Externally Heated Desiccant Air Dryer:

- These dryers are typically used in petrochemical, chemical and heavy manufacturing industries.

Refrigerated Air Dryer

The Refrigerated Air Dryer cools the compressed air sufficient to condense and purge moisture resulting in a lower dew point for an effective cost-saving and energy-efficient drying solution for most industrial applications.

Benefits of using Refrigerated Air Dryer:

- Dew point around 3°C

- Simple non-cyclic operating process

- Environmentally friendly refrigerants

- Compact, reliable, and a maintenance-free design

Application of Refrigerated Air Dryer:

- The Refrigerated Air Dryer is typically utilized in food & beverage, textile, automotive, and general manufacturing industries.

Technical Specifications of Compressed Air & Gas Dryers

| Model Type | Dew Point Range | Flow Capacity | Working Pressure | Power Consumption | Purge Loss |

|---|---|---|---|---|---|

| Heatless Dryer | –40°C to –60°C | 10 – 5000 CFM | Up to 10 kg/cm² | Low | 15% |

| Internally Heated | –60°C | 10 – 5000 CFM | Up to 10 kg/cm² | Moderate | 7–10% |

| Externally Heated | –70°C | 50 – 5000 CFM | Up to 10 kg/cm² | Medium | <5% |

| Refrigerated | +3°C | 10 – 5000 CFM | Up to 10 kg/cm² | Low | 0% |

Features of Compressed Air & Gas Dryers

- Compact and modular system construction enables easy installation

- High efficiency in moisture removal

- Energy-efficient and minimal maintenance needed

- Microprocessor/PLC control options available

- Skid-mounted plug-and-play units

- All made from stainless steel and other corrosion-resistant materials

- Industry-certified manufacturing to ISO 9001:2015 & ISO 13485: 2016

Industries which uses Air & Gas Dryers

The Compressed Air & Gas Dryers can be used across various industries:

- Pharmaceuticals & Biotechnology

- Food & Beverage Processing

- Petrochemical & Chemicals

- Automobile Industries & Engineering plants

- Hospitals & Health Care

- Textiles & Packaging Units

- Power Plants & Refineries

Why Harsiddhi Air Solution?

- Decades of experience in Air & Gas Treatment systems

- Custom designed dryer solutions for industrial commercial and medical use

- Advanced PSA and desiccant technology

- ISO certified quality management system

- PAN India service and support network

- Focus on sustainability and energy efficiency

At Harsiddhi Air Solution everything about the system is built to maximum performance, reliability, and longevity. Clean, dry air, and always.

FAQs on Compressed Air & Gas Dryers

Q1: What is the use of a Compressed Air Dryer?

A: The Compressed Air Dryer eliminates moisture and contaminants from compressed air, ensuring safe use for your equipment, and retains high air quality and moisture control for industrial or medical applications.

Q2: Which type of air dryer is suitable for my industry?

A: This will depend on your desired dew point, as well as the air flow. Desiccant dryers are preferred when extreme dryness required (-40 degree Celsius to -70 degree Celsius), and refrigerated dryers are preferred when standard dryer applications are required (+3 degree Celsius).

Q3: What is the difference of a Heatless to Refrigerated Air Filter?

A: The heatless dryers use an adsorption and (not a heating source) for very low dewpoint applications. Generally, the refrigerated dryers work off of the cooling process that is normal operation of most air systems.

Q4: How often do I change desiccant?

A: Typically 2-3 years, depending on air quality, air operating hours and maintenance.

Q5: Am I able to install a dryer into an existing compressed air system?

A: Yes, our dryer can be integrated into all existing compressor brands and can be added easily to the existing system.

Q6: Do you provide after sales service and AMC?

A: Yes, we provide the installation, commissioning and annual maintenance contracts across India.

Get in Touch with Us

📍 Harsiddhi Air Solution

B-26, Ved Industrial Park-2, Kathwada, Ahmedabad, Gujarat, India

📞 Phone: +91 9023435128

📧 Email: info@harsiddhiairsolution.com

Get the exceptional quality and performance with India’s premier manufacturer of Compressed Air and Gas Dryers. Upgrade your air system now for increased performance, longer life, and decreased energy consumption.